The term Differential pressure literally means the difference amongst the two pressures that have been applied. If the pressure at a random point, let’s say A is 20psi & the pressure at another point B is 10psi, then the differential pressure will rest at 10psi (20psi – 10psi). When it comes to measuring it, Differential pressure sensors are available for the task. A differential pressure gauge is available at your disposal; you can find them installed in almost every industrial process system. Differential pressure sensors come handy, they are the visual indicator that is designed specifically for the purpose of measuring and explaining the difference amidst the 2 pressure points.

The working of a Differential pressure sensor-explained

When it comes to working with the differential pressure sensors, they operate on a simple principle of recording pressure at two different points and providing the user with a difference which is the result of internal calculations. In other words, the flow rate is dependent on the differential pressure produced. Differential pressure transmitters are not meant to fix the references. An increase in the differential can be due to the increase in individual pressure of any of the point or even the decrement of pressure at any of the point respectively.

The Differential pressure calculation is not dependent on the fact whether the two pressures are getting recorded at vacuum or atmospheric pressure. The main aim or task of the Differential pressure is to record and calculate the respected difference between the two distinguished pressures.

These type of Differential pressure sensors are used in domestic as well as industrial level applications on a large scale. One of the most common applications for which Differential pressure sensors are widely used is Differential pressure flow measurement. You can calculate the flow rate of the fluid in the pipe with the help of a Differential pressure sensor.

In the majority of Differential pressure meters, there are two elements, primary & secondary. The function of the primary element is to produce the slightest of the difference as soon as an increase in the pressure appears. The orifice plate is one of the most preferred and well-known primary element of the Differential pressure sensors. Other types are pitot tube, venture and more.

When it comes to the second element, it is a Differential pressure sensor. The device has been manufactured to accurately record the differential pressure produced by the first element. As a matter of fact, aspects like temperature, changing fluid pressure can cause errors in the final calculations, therefore Differential pressure measurement is used as it remains unaffected.

You can say a proficient Differential pressure sensor will always measure the correct differential pressure regardless of the ever-changing parameters. The device must always transmit the signals for the purpose of depicting differential pressure. The sensors can be of great worth when measurements of high accuracy are required.

What are differential pressure transmitters?

The differential pressure transmitter is one of the most reliable as well as a useful instrument for measuring the differential pressure. A Differential pressure transmitter is capable of sensing the difference in between two pressure ports, the device produced high-quality output signals.

A proficient Differential pressure transmitter will make a seamless measurement of differential pressure and will also transmit the output signals. Generally, the output signals are of 4-20mA potential. Digital communication aspects such as Modbus 485, HART and much more are also possible with a Differential pressure transmitter. The prime objective of the device is to generate and send an electrical signal to an instrument which can do the remote processing.

If you’re wondering about how Differential pressure transmitters are made? Well, the device is generally made up of two housings. The element which is responsible for sensing the pressure is present in the bottom house, while the electronic amenities gets housed in the upper half. The device features two pressure ports with the tags “High” & “Low”. Though, it’s not always necessary to follow the markings, as the pressure at the high port may not always remain high.

As mentioned above, the pressure sensing element rests in the lower section of the device, generally, a diaphragm is the preferred pressure sensing element. The element falls under the category of the mechanical device; it is placed amidst the 2 inlet pressure ports. The element will deflect whenever there is a change in the applied pressure. Later, the physical deflection is converted & recorded in the form of electrical signals, the work here is accommodated by sensors.

Major sensors that are used for converting deflections to electrical signals are Vibrating wires, strain gauges and differential capacitors. What comes as an interesting fact is that, the electronic unit generated by these sensor ranges between few milli-volts only. The signals are then amplified to a considerable voltage range of 0-5V. If a remote transmission to any instrument is required, then it’s again converted to 5-20mA range.

For the output, a DC current gets produced which varies with the differential pressure hand in hand.

In simpler words, the more the differential pressure, the more is the DC output current produced. The interesting feature here is that output current is independent of load impedance vibration as well as voltage fluctuations during the supply.

Let’s talk about applications of the industry level Differential pressure transmitter:

- Differential pressure transmitters are extensively used for the purpose of pump control monitoring.

- These can also cater to monitoring the pressure drops across valves.

- For subsea applications, Differential pressure transmitter provides flow metering for both Oil as well as Gas respectively. You can also use the device in offshore & onshore apps.

- Sprinkling system monitoring just got pretty much easier with the aid of Differential pressure transmitters.

- You can remotely sense the changing heat or steam of the heating systems easily.

Differential pressure sensors for Air:

Differential pressure sensors offer an accurate measurement of low-differential pressure of the air. You may also inculcate the device for non-corrosive gases. A good Differential pressure sensor can provide the user with a reliable, long-term & a fast service. These types of sensors that are meant for measuring the difference in the pressure in the presence of air are fully calibrated as well as the temperature compensated. Due to these, the range of Differential pressure sensors for air offers the highest level of accuracy to the user, even at the low-differential pressure cases.

Compact design is what makes them unique, these type of sensors can be your best pick for medical or HVAC applications as well. The presence of ultra-thin crystal diaphragm (silicon made) capacitive sensor is what the device is thriving upon. The element can provide the user with accurate readings with stability with no errors. What comes as a great fact is that, Differential pressure sensors for aid doesn’t degrade with time.

When it comes to sizes, the Differential pressure sensors for air are available for an array of measuring sizes. From 0.1 inches to 25 inches of any water column, you can measure the reverse pressure by a negative pressure sensor, also, positive as well as bi-directional pressures can be measured too. Major Differential pressure air sensors can withstand a pressure of over 15 psi with much ease and without any calibration shift.

If you’re thinking of installing one, then it’s pretty easy. With the help of removable terminal blocks, rugged ABS housing and the brass pressure ports, you can mount a pressure sensor in no time. When it comes to features of these Differential pressure sensors for air, their accuracy stands at plus minus 1%. The pressure range accommodated is from 0.1 inches w.c. to 25 inches w.c. The sensing element features an unparalleled level of constancy to the user.

Differential pressure sensors for water & liquid:

For the purpose of calculating the pressure in the sealed tanks, Differential pressure sensors for water & liquid are of great worth. Majority of the sealed tanks have an invisible blanket of atmospheric gas on the top of standing liquid. The blanket pressure is also termed as Vapor pressure in thermodynamics. The Vapor pressure adds with the hydrostatic pressure which has been created by the standing water.

The problem is that; the resultant pressure makes it difficult to attain accurate pressure reading just by using a pressure gauge. Differential pressure sensors for water & liquid are there to your rescue, especially when it comes to measuring a correct pressure in the sealed tanks.

These type of pressure sensors can also be used in injection wells for the purpose of measuring the difference amongst the reservoir’s pressure to that of bottom holes pressure. When it comes to measuring the pressure difference of reservoir pressure & injection pressure, Differential pressure sensors for water & liquid performs a great job.

The sensors can perform the task of measuring the liquid’s flow in a pipe pretty easily. For reducing the diameter from the inside of a pipe, the orifice plate is the preferred choice. Differential pressure sensors for water & liquid measures the flow rate by computing the difference of the pressure recorded before & after the orifice plate. There are generally three design options available under this category, piston-type, bi-diaphragm or double-diaphragm & an all-welded type variants are available.

The piston-type pressure sensor is best suited for clean water, in other words, it can cater to the pressure measurement needs where there is low differential pressure. These are also available with a separating diaphragm module for applications such as liquid level ones.

The double-diaphragm sensors are used when a calculation is required for a high-pressure environment in combination with a low-differential pressure. These are generally equipped with face plates for a maximum level of security. The pressure range accommodated is as high as 3600 psi.

All-welded sensors are used mainly for the environments that are corrosive in nature. High media temperatures, system vibration, pulsation kind of environments require an all-welded pressure sensor.

Differential pressure sensors for gas:

If you require to monitor the differential pressure of gases and if they are non-inflammable & non-aggressive in nature, you can use a compact Differential pressure sensor. Best suited for monitoring the pressure in the clean rooms as well as filters. Room pressure sensor can be the best choice for this propose. These type of Differential pressure sensors for gas can produce an output signal of voltage ranging from 0 to 10 Volts.

The upper-pressure measurement operating limit stands at 20 kPa for a majority of Differential pressure sensors for gas. The maintenance and mounting of these are easy and rigid. Talking about the features, these type of sensors are very flexible in nature & highly adaptable. Mainly used in ventilation industries, a user can see the measured value of pressure transmission and differential pressure on a display. The intuitive operation leads to a robust appeal of the device.

These can also be incorporated in food packaging industries, processing industries, semiconductor industries and much more. Differential pressure sensors for gas provides an error of plus-minus 2%. What comes as a great fact is that, a majority of Differential pressure sensors for gases comes with an energy-saving mode as well.

Differential pressure sensors for HVAC systems:

It would be right to say that with the growing demand of building maintenance, HVAC systems are falling short of meeting the demands. The pressure sensor can play a great role when it comes to monitoring the building for the purpose of keeping occupants safe and secured. HVAC, when integrated with the pressure sensor technology, can operate at finest levels with much ease.

Since quality control is always important, pressure sensors measure the pressure changes & in a case of any predicament, it informs immediately. Differential pressure sensors for HVAC can easily measure the pressure drop amongst the rooms, with advanced features, room pressure sensors for hospitals can be deployed as well. They can also generate alerts for the cleaning of the filters. For critical application needs, such as stairwell pressurization, you can rely on Differential pressure for HVAC systems. For improving the quality of indoor air, pressure combined with HVAC systems can do wonders for you. Generally, buildings do require a certain level of airflow, you can obtain the data with the aid of a pressure sensor within seconds.

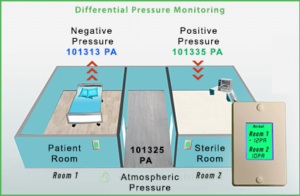

Differential pressure monitoring for hospital rooms

There are many applications of differential pressure in hospitals, laboratories etc. Few of the applications are isolation wards, operation theaters, CSSD rooms etc. One of the rooms will be either in positive pressure or negative pressure compared to the outside. This is to prevent spreading of viruses or bacteria. It is absolutely essential to maintain the pressure difference in these instances. For any change in pressure the system will generate an alert such as phone call, SMS, a local siren etc.

There will be a display screen in front of the room so that operating personnel can check the same. The screen also has alerts to indicate if the required pressure difference is not correct.

The rooms are also called positive pressure room, negative pressure room etc. based on the pressure.

Differential pressure monitoring for clean rooms

Similar to hospital rooms, industrial or research clean rooms also require similar systems. In order to ensure that the clean rooms are absolutely sterile, we keep slightly positive pressure. In case the pressure in the clean room approach that of the outside it will generate a local alert or phone call alerts.

Vacker differential pressure monitor model VAC-P-008 for hospitals

We provide wide range of pressure monitoring systems for all type of commercial and industrial applications. These models come with a display to indicate the absolute pressure and the differential pressure.

| Model | CPS6000 |

| Applications | CSSD rooms, clean rooms, Operating rooms, Isolation rooms, Laboratories |

| Type | Flush-mounting type and box mounting type |

| Dimension | 152 x 102 x 5 mm |

| Display type | LCD Touchscreen |

| Color of the panel | white |

| Communication channels | RS485 & Modbus |

| Measurement on the wall box | 150x100x40 mm |

| Power supply | 24 V DC adaptor |

| Measurement range | +- 250 pascal (Other on request) |

| Accuracy | 0.5 pa (full range) |

| Output parameters | 0-10, 1-5, 0-5, 2-10 Volt, 4-20, 0-20 mA |

| Range for analogue output configuration | 5, 10, 25, 50, 75, 100, 125, 175, 200, 225, 250 |

| Output signals | Optional Relay output for generating phone call alert, SMS alert etc. |