No one wants to have their water tank or other liquid tank overflowing. That accident is a waste of money, resources and time. Cleaning the mess can be costly as well. It doesn’t matter the size of the tank or the contents, one needs to know when the tank is full or at the desired level. That is why a good liquid monitoring system.

No one wants to have their water tank or other liquid tank overflowing. That accident is a waste of money, resources and time. Cleaning the mess can be costly as well. It doesn’t matter the size of the tank or the contents, one needs to know when the tank is full or at the desired level. That is why a good liquid monitoring system.

Type of Tanks

There are many varieties of tanks that are used in storing either water or other liquids. These are water tanks, bulk storage tanks, petroleum tanks, oil tanks, sewage tanks and many more. They all come with a variety of monitoring systems.

Floats

One of the oldest methods of monitoring water or other liquid levels is the float system. This system simply employs an air filled ball which rises with the water. The float is connected to a lever and when it reaches a certain pre-determined height, the float activates the lever which shuts off the water.

Ultrasonic level sensor

One of the modern advances to the air ball float system has been the upgrade to ultrasound. Also known as an ultrasound level gauge this metering system sends a signal to the bottom of the tank which then bounces back to the top at a predetermined speed. This method provides an accurate reading of the current water or liquid level.

Radio wave liquid level indicators

The only difference between this method of liquid monitoring and the ultrasound method is that this method uses radio waves instead of ultrasound signals.

Microwave liquid level transmitters

The same goes for this system. Microwave signals are used instead of radio or ultrasound transmissions. In each case the transmitter for each is placed at the top of the tank for the best monitoring service.

Hydrostatic liquid level switch

This method of liquid monitoring does not employ high tech signals but depends upon the pressure created by the rising water. Each level has its own weight so it is easy to measure the liquid level by the amount of pressure applied to the switch.

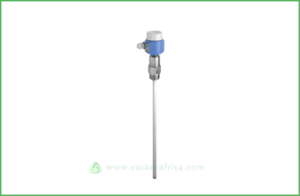

Capacitance liquid level measurement sensor

It is a big word and title but the duty is simple. Electricity is used to determine the level of the liquid being monitored. How it works is the amount of electricity stored by the body of the liquid determines its height. The greater the storage of electricity, the higher the liquid level.

Common Monitoring Systems

Out of all the different systems available to monitor different liquids the most common sensors are the float and ultrasound methods. The drawback to the float system is that it can only indicate when the liquid has reached the designated preferred level. It cannot indicate any levels prior to that objective. The popularity of the float system is that it is inexpensive and it comes in stainless steel versions as well when monitoring more corrosive liquids.

Silo Monitoring

This is an alternative to liquid monitoring and uses ultrasound to monitor the levels of the grains, cement or other no liquid product you would like to monitor.

Integration

Our systems can integrate with most automated systems. It would be best to contact our company and talk to our integration experts. It will all depend upon the system you are currently employing to make integration work.

Alerts

It is possible to set up an alert system when the liquid is reaching critical levels. This emergency is usually due to the motors not shutting off when the sensors instructed them to turn off. These alerts can contact up to 8 people and send a pre-recorded message informing them of the emergency.